Want to know more about our ultrapure water, including what grade it is and how we make it?

In our short video, you’ll follow the step-by-step process of manufacturing ultrapure water as one of ReAgent’s directors, Jessica Clifton, explains how impurities are removed from feedstock water.

What is the video about?

Watch Jessica walk you through ReAgent’s process of manufacturing ultrapure water.

She explains how we provide a wide range of options in terms of volumes, from small containers to 1,000L IBCs and 25,000L road tankers.

In the video, you’ll learn how:

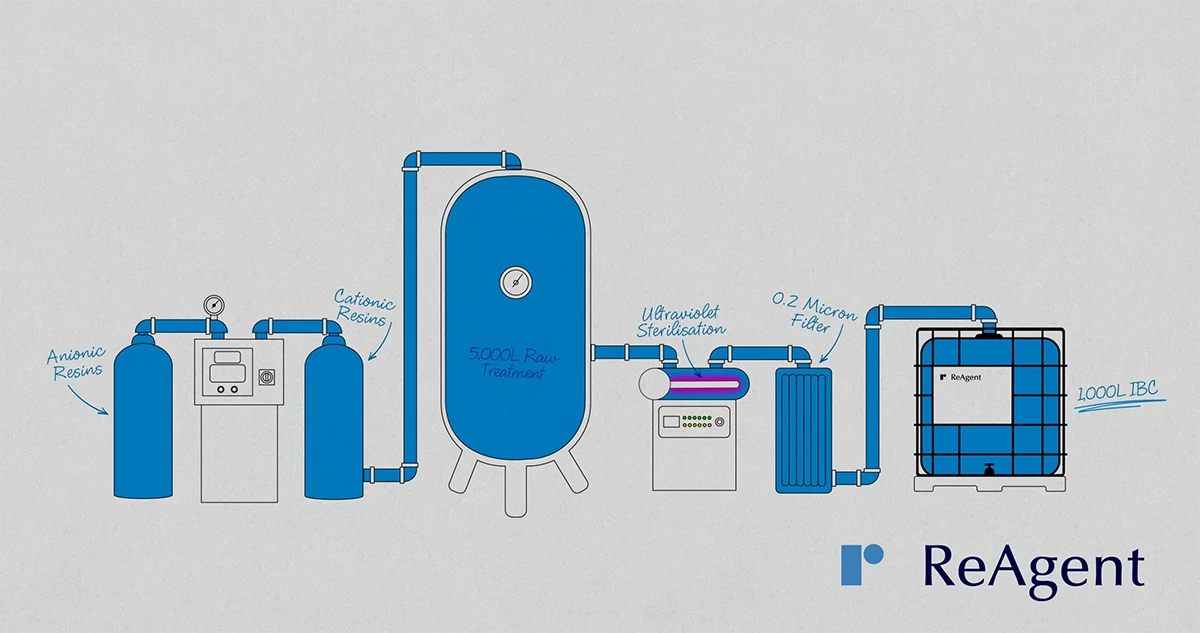

- ReAgent provides a wide range of options in terms of container sizes, including custom option

- The starting material is mains water

- As the initial step, suspended debris and particles are removed using a pre-filter process

- A twin-bed deionizer is then used to remove the anions and cations in the water, effectively demineralising it

- The water is then passed through ultraviolet irradiation and 0.2-micron filtration to kill bacteria and remove other microscopic impurities

- The water then undergoes testing to ensure it consistently meets quality standards

- We hold ISO certifications, ensuring the dependability of our ultrapure water products for laboratory and industrial applications

By choosing ReAgent as your supplier, you can be assured of the top quality and consistency of the ultrapure water that you order.

Contact us today for your ultrapure water needs.